Drive Efficiency through Improved Decision-Making

Decision-making in terminal operations is complex and intricate. Each decision has multiple flow-on decisions that in turn complicate future decisions. As a result, terminals have steadily increased their use of software – specifically, Terminal Operating Systems (TOS) – to gather critical data together and present the clearest picture to operators needing to make complex decisions. As a first step this is good, but with all first steps, there are limitations on what can be achieved. In an increasingly competitive market, operators are now faced with the need to not only make decisions but, rather, make decisions that represent the best value to the terminal. This is where add-on Agile Optimization Modules for existing TOSs add significant value.

Table of Contents

Decision-Making in Terminal Operations

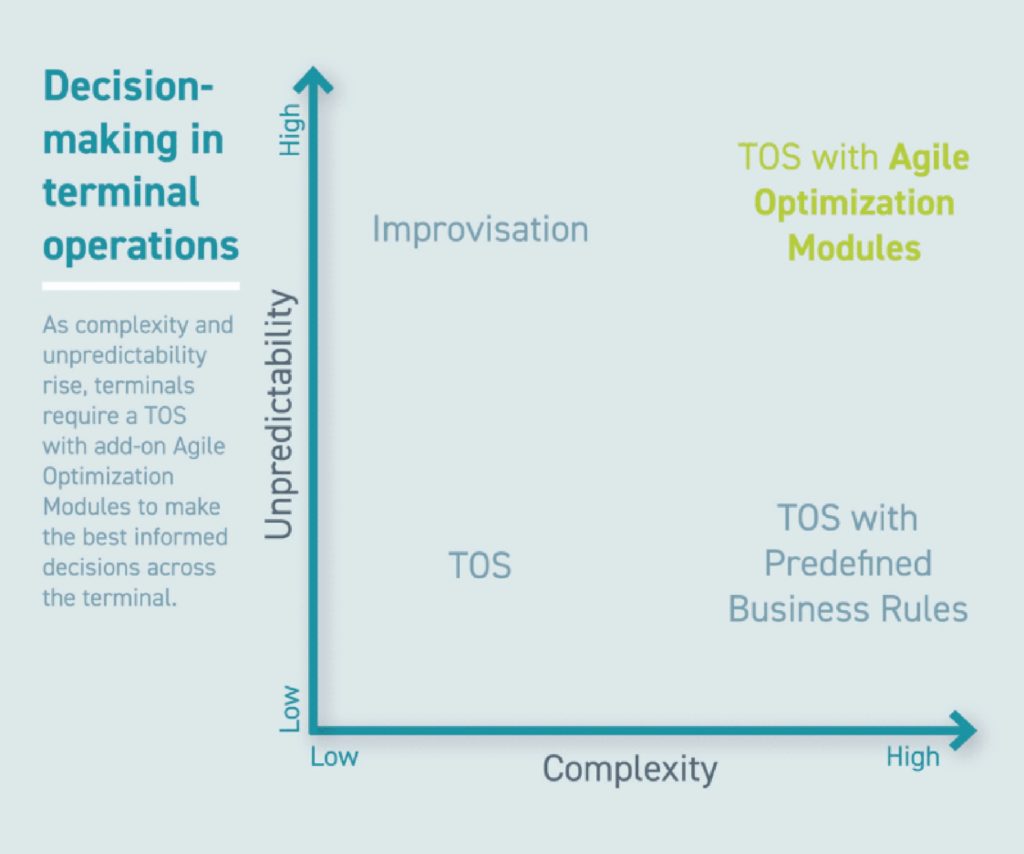

There are two factors that impact decision-making in terminal operations: complexity and unpredictability. Complexity is straightforward: how complicated is the terminal environment (e.g., a highly standardized terminal with few moving parts or one with many interdependencies and variants)? As a rule of thumb, the bigger the terminal, the more complexity it has. Unpredictability involves the relationship between internal terminal processes and external factors (e.g., stability of terminal procedures, ample planning time, and minimal disruptions vs. unpredictable events, ad hoc orders, time pressures, and volatility). Even the best-planned terminals have a high degree of unpredictability as daily operations exist in the real world, where all factors can’t be accounted for. In terminals with low complexity and low unpredictability, a TOS is sufficient to support the decision-making process. As complexity rises, more advanced decision support is required, such as a TOS with predefined business rules. When unpredictability increases, the operational plan must continuously change to accommodate unexpected disruptions and ad hoc changes. It is in these environments that terminals require a TOS with add-on Agile Optimization Modules to make the best-informed decisions.

Algorithms Drive Agile Optimization

Agile Optimization allows operators to make incredibly complex, time-critical decisions in real time. What’s more, the decisions made take into account a larger range of variables than the human mind can, resulting in better overall decisions. This in turn leads to increases in efficiency across the terminal. At its core, algorithms drive Agile Optimization. Over the past 20 years, improvements in computer hardware have resulted in an increase in computing power by a factor of 1,200 times. This seems impressive until one compares it to the advances in optimization algorithms over the same period; algorithms have improved by a factor of 55,000 times. When combined, the effects of both advances generate a tremendous 66 million times improvement in processing capability. To exemplify this, a planning model using linear programming would have taken two years to solve in the ’90s; today, it can be solved in a second.

Add-On Power

Agile Optimization Modules do not replace an existing TOS, but rather work in conjunction with it to drive terminal efficiency. This “add-on” relationship allows terminals to implement the power of Optimization Modules without significant changes. While deployment time frames vary from case to case, it is measured in months, making it quick in comparison to a typical TOS implementation. Further, in most cases, Optimization Modules work in the background without direct user interaction. Users interact with their existing software environment while benefiting from optimization with no timely retraining required.

Efficiency across the Terminal

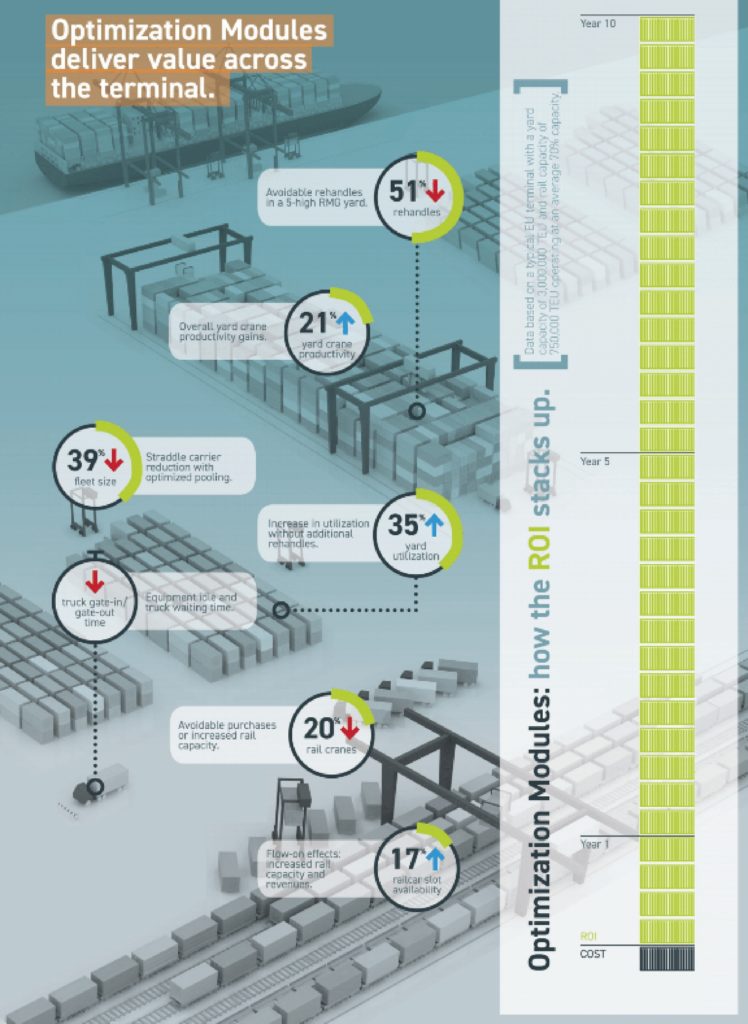

Optimization Modules deliver value across the terminal. As decision-making is improved, efficiency is realized across the terminal in both the short and long terms as highlighted in the infographic. Short-term savings often translate directly to the bottom line. Efficiencies such as reductions in vehicle travel, crane travel, and yard rehandles are the easiest to see and calculate. Long-term savings as well as potential revenue increases can be harder to see initially. Reductions in overall handling equipment as well as delaying or avoiding new equipment purchases happen slowly as operators adjust operational procedures to maximize the efficiency gains possible. Further, increasing yard, truck, and rail handling capacities are intangible results that are the byproducts of more efficient terminals. All of these long-term outcomes deliver significant value.

The Case for Optimization Modules: A CTA Story

In early 2015, HHLA Container Terminal Altenwerder (CTA), Hamburg, Germany, approached INFORM with a unique request – they wanted to expanded their rail terminal’s capacity by adding two additional tracks and do it without compromising their customer service. The expansion had to utilize the existing terminal footprint. Subsequently, to add the two new tracks, six of the seven existing tracks had to be disassembled, moved, and reassembled to allow space within the existing terminal footprint. Throughout the project, the terminal’s rail capacity was substantially reduced. The project was delivered in August 2016; it was completed in two phases that took four months to complete. INFORM’s Agile Optimization Modules helped Germany’s largest container rail terminal to expand their capacity without compromising on customer service. The project’s most complex construction scenario included three of the existing seven tracks closed, reducing the site capacity by 42%. Additionally, the rail cranes were not allowed to move load units over the construction zone.

SYNCROTESS

Add-on Module

Rail Scheduler improves the utilization of transfer points between your rail and yard while increasing rail crane and yard vehicle productivity.

Syncrotess was able to adapt easily to the changing construction scenarios. Among many innovations within the project, INFORM’s Optimization Modules were configured with “virtual construction fences” that enabled the system to adhere to the constraints of the construction scenarios while managing the workload efficiently. The expansion increased CTA’s rail terminal capacity by 140,000 TEU, to approximately 930,000 TEU per year. The Agile Optimization Modules allowed for the increase in capacity with no additional rail cranes needing to be purchased and installed, saving CTA both money and time.

Efficiency beyond the Terminal

Container terminals are surrounded by, and depend on, a large number of related facilities: intermodal terminals, rail terminals, empty container depots, and distribution centers, to name a few. In essence, container terminals form the heart of a complex logistics network. Agile Optimization Software developed for peripheral industries can provide solutions to container terminals for managing efficiency beyond the terminal, and this in turn leads to greater efficiency within the terminal.

Empty Container Management

Empty container management is a technique used by manufacturers, wholesalers, and retailers globally as a means of improving how reusable containers cycle between various stakeholders. It delivers many features, ranging from improved container availability through to decreases in required container stock. When applied to container terminals, empty container management represents an untapped cost-control mechanism for terminal operators and service providers utilizing the terminal network.

SYNCROTESS

Add-on Module

Vehicle Optimizer increases vehicle utilization across all equipment types while reducing travel and lowering maintenance costs.

Container Transport

Further, using Agile Optimization Software to generate and schedule corresponding transport orders in real time allows operators to monitor transport execution, fostering continuous transparency and reducing the burden on terminal infrastructure. In this way, empty container transport systems should be configured to utilize off-peak hours for shifting empty containers to mitigate gate and terminal congestion.