In 2019, INFORM undertook the ambitious step of embracing the United Nations Sustainable Development Goals (SDGs). The UN SDGs challenge companies to replace profit maximization with a multifactor success model that adds “people” and “planet” to the traditional “profit” success factor. We were challenged to assess how we were, or could begin, contributing to the 17 SDGs. This challenge kicked off what has now been a two-year journey assessing our impact in the maritime sector.

Table of Contents

In 2019, we launched our first diversity initiative. In 2020, we brought innovation to the intermodal industry to drive environmental impact and launched initiatives designed to help educate children as well as help foster gender equality in maritime. And, as 2021 kicks off, we’ve completed research to understand how four more of our AI-based optimization modules drive environmental sustainability for terminal operators.

This paper will look at INFORM’s sustainability work across four of the SDGs: No. 4 – Quality Education, No. 5 – Gender Equality, No. 9 – Industry, Innovation, and Infrastructure, and No. 13 – Climate Action. They are separated by the same headings, with the first three sections looking at various initiatives we’ve undertaken over the past two years. If you want to cut to the chase and understand how to reduce your costs while simultaneously driving down your carbon footprint, then jump to No. 13 – Climate Action; in it, we detail how four more of our optimizers drive environmental sustainability.

No. 4 – Quality Education

In 2020, challenged by the COVID-19 pandemic and a lack of products in supermarkets across the globe, we created our Logistics@Home self-learning pack to help children understand how the global supply chain worked. This learn-at-home resource has been made available in two languages with thousands of downloads to date, proving that interest in understanding the way goods are moved around the world is high. Our children are our future, and this initiative is helping children worldwide understand the logistics industry, in which maritime and intermodal operations serve a crucial role.

CLICK HERE FOR INFORM´S LOGISTICS@HOME

No. 5 – Gender Equality

The fifth SDG focuses on gender equality. At INFORM, we have expanded this to a broader scope of diversity in all of its forms. In 2019, we kicked off the industry’s first age-diversity initiative, Millennials in Maritime, at TOC Europe. In it, we provided a platform for millennial-aged speakers to come together and contribute to the industry’s knowledge base. We continued this program in 2020 and are committed to bringing it back to this year’s TOC Europe event again.

READ: WHY GIVE MILLENNIALS A VOICE?

In 2020, we also kicked off our gender-diversity initiative, Women in Maritime, through a series of one-on-one interviews with women from across the maritime world. It features voices from the terminal sector such as Katja Otten from AMPT, Susan Gardner from GPA, and Swantje Finke from HHLA as well as a host of guests from the broader maritime industry, including Anne Trolle from Danish Shipping, Jennifer Sommer from HPC, and Heidi Heseltine, founder of the Diversity Study Group. This initiative has reaffirmed our original decision to expand gender equality to diversity equality. We’ve also committed to expanding this program with additional interviews being released monthly throughout 2021, a live conference event at TOC Europe, and industry partnerships.

DELVE INTO WOMEN IN MARITIME HERE

No. 9 – Industry, Innovation, and Infrastructure

In January 2020, INFORM published its first paper, “Going Green with AI” (Port Technology Edition 90), about how our AI and optimization software, specifically our Train Load Optimizer (TLO), was driving environmental sustainability outcomes within the intermodal rail sector. In that paper, we highlighted one of our innovative algorithms that stood to drive significant cost savings and CO2 reductions for rail operators. On a single leg of the rail route from Los Angeles to Chicago, it was estimated that our TLO could save rail operators EUR 6,000 (USD 6,500) and reduce CO2 by 22.2 tons. At face value, these numbers aren’t impressive; however, when you scale that route up, it would equate to a reduction in CO2 of at least 6,925 tons.

FURTHER READING: GOING GREEN WITH AI

No. 13 – Climate Action

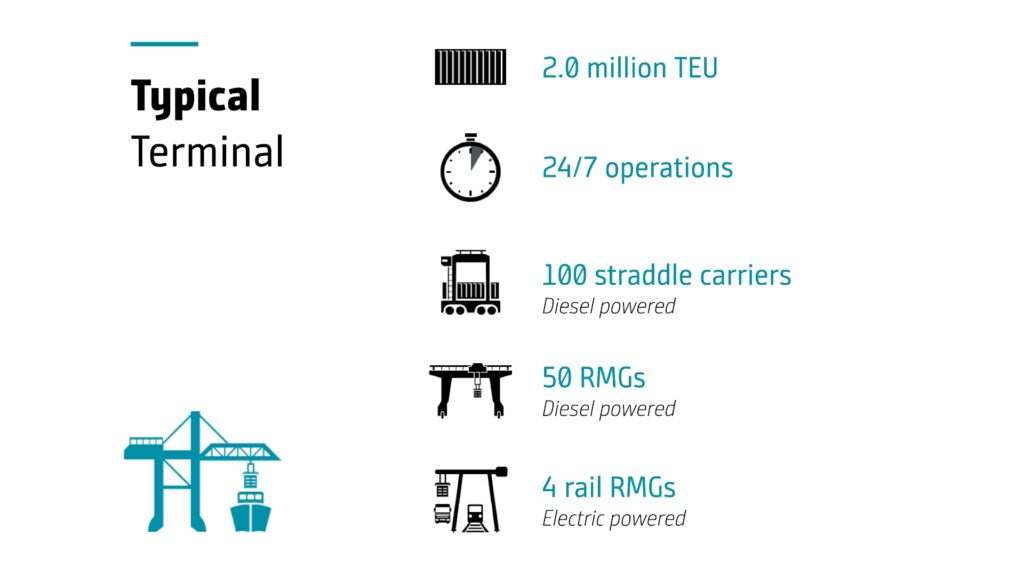

Optimization software isn’t new to the industry. After all, INFORM has been helping maritime operators reduce cost and drive-up efficiency for 25-plus years. What is comparatively new is our industry’s focus on environmental sustainability. Throughout 2020, we’ve been busy conducting research into understanding how four of our industry-proven add-on AI optimization modules contribute to climate action. We’ve compiled research on our Vehicle Optimizer (VO), Yard Optimizer (YO), Machine Learning (ML) module, and Time Slot Management (TSM) system. All calculations are based on a “typical” maritime terminal, as outlined in Figure 1.

Vehicle Optimization

Vehicle Optimizer is a dynamic add-on module typically deployed to reduce empty travel at a terminal. When deployed to reduce empty travel in a straddle carrier fleet, on average, we see a 20% reduction in empty travel. In our typical terminal, this would result in an OPEX cost savings of EUR 5.2 million (USD 6.3 million) annually. From an environmental perspective, it would prevent 16,200 tons of CO2 from being produced.

Yard Optimization

The primary driver of our Yard Optimizer is the desire to reduce costly rehandlers. We typically see a 45% reduction in yard rehandles when compared to a TOS-only planning strategy in straddle carrier yards. This drives an OPEX cost savings of EUR 7.5 million (USD 9.1 million) per annum. Again, from an environmental perspective, this drives a reduction of 1,580 tons of CO2 annually.

Machine Learning

Contemplated in 2019 and introduced into live operations at HHLA’s Container Terminal Burchardkai (CTB) in Hamburg, Germany, our Machine Learning module’s first implementation was designed to improve container data accuracy. Based on our original assessment and our experience at CTB, we expect that a typical terminal will see a further 10% reduction in rehandles. Annually, this would drive an additional OPEX cost savings of EUR 1.7 million (USD 2.1 million) in addition to our Yard Optimizer. This additional reduction in rehandles reduces the CO2 footprint of a terminal by an additional 350 tons annually.

In live operations, we have also observed a further reduction of vehicle travel as a flow-on benefit. In our typical terminal configuration, it’s expected that vehicle travel would be reduced by a further 10%. This stacks up to an additional OPEX cost savings of EUR 2.6 million (USD 3.2 million) yearly. Environmentally speaking, this would drive down CO2 emissions by a further 8,100 tons per year.

Time Slot Management

Time slot management systems are implemented to reduce gate congestion and subsequent truck queue times. A typical terminal will see a reduction in truck waiting times of 75% when implementing TSM. While the cost-benefit is to the trucking companies in diesel fuel savings, it does add up over the year. Based on the cost of diesel fuel in Germany when writing this, it would equate to EUR 0.7 million (USD 0.9 million). Environmentally, the reduction in diesel engines idling at a terminals gate would prevent 400 tons of CO2 from being produced annually.

Understanding CO2 Savings

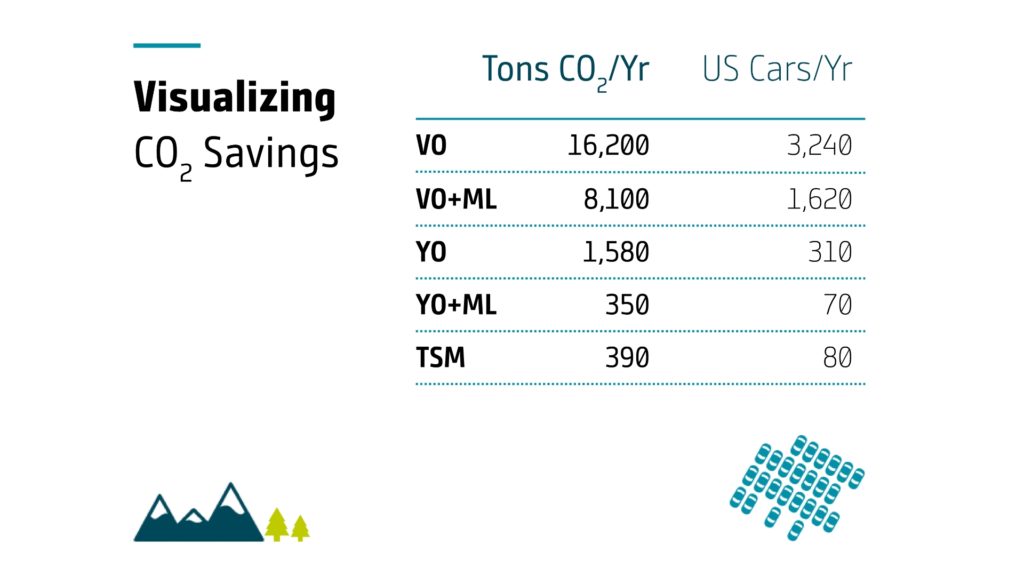

To help you understand the impact of reducing CO2, it is helpful to understand what preventing one ton of CO2 equates to. According to the US Environmental Protection Agency (EPA), the “average” passenger vehicle emits about 250 g CO2/km (400 g CO2/mi). In other words, an average passenger vehicle in the US will produce one ton of CO2 for every 4,000 km (2,500 mi) driven. Furthermore, the average passenger vehicle is driven 20,000 km (12,420 mi) annually, meaning a passenger vehicle in the US will produce 5 tons of CO2 yearly, on average. In simple terms, every 1,000 tons of CO2 we prevent from being produced is the equivalent of removing 200 cars from US roads each year. Figure 2 shows how many passenger vehicles are removed for each of the optimization examples highlighted above.

While the environmental benefits of our AI optimization software will certainly vary from terminal to terminal given their unique operating conditions, the end results will remain – there are both cost savings and environmental benefits to software-based optimization. The best step toward understanding the impact on your terminal is to start a conversation with an INFORM optimization specialist. Our team brings decades of experience and a proven simulation process designed to help terminal operators understand the benefits of optimization – both financially and environmentally.

Add-on “Sustainability”

Artificial intelligence (AI) is seemingly popping up everywhere we look these days. As a niche AI system provider, INFORM has been delivering AI solutions for just over two decades. Within the maritime sector, Optimization Modules deliver value across terminals. As decision-making is improved, efficiency is realized across the terminal in both the short and long terms. Short-term savings often translate directly to the bottom line. Efficiencies such as reductions in vehicle travel, crane travel, and yard rehandles are the easiest to see and calculate.

Long-term savings, as well as potential revenue increases, can be harder to see initially. Reducing overall handling equipment and delaying or avoiding new equipment purchases happen slowly as operators adjust operational procedures to maximize efficiency gains. Furthermore, increased yard, truck, and rail handling capacities are intangible results that are the byproducts of more efficient terminals. All of these long-term outcomes deliver significant value, and through these activities, substantial environmental sustainability outcomes can be achieved simultaneously.

INFORM’s Optimization Modules do not replace an existing TOS, but rather work in conjunction with it to drive terminal efficiency. This “add-on” relationship allows terminals to implement the “green” power of Optimization Modules without significant changes. While deployment time frames vary from case to case, they are measured in months, making deployment quick compared to a typical TOS implementation.

Sustainability at INFORM isn’t just a buzzword that we’re jumping on to sell our products. In fact, it is an integral part of the culture at INFORM. By way of example, our team, while based in Germany, comes from over 30 different nations. From the top of our organization to the bottom, we’re committed to improving the “people” and “planet” outcomes directly and indirectly connected to our company and to the industry we serve.